Basic Information

Place of Origin: | Qingdao, China |

Brand Name: | TSKY |

Certification: | SGS, ISO, BV, CE |

Model Number: | As per the customer's demand |

Minimum Order Quantity: | 50 pieces |

Price: | Negotiation |

Packaging Details: | Export standard container: 20GP or 40GP, 40HC |

Delivery Time: | 7-15 working days after confirmed order |

Payment Terms: | L/C, T/T, Western Union |

Supply Ability: | 30000 pieces per day |

Detail Information:

Model: | As Per The Customer's Demand | Color: | According To The Customer's Request |

High Light: | SGS HDPE roller, non magnetic HDPE Roller, SGS polymer roller | ||

Product Description:

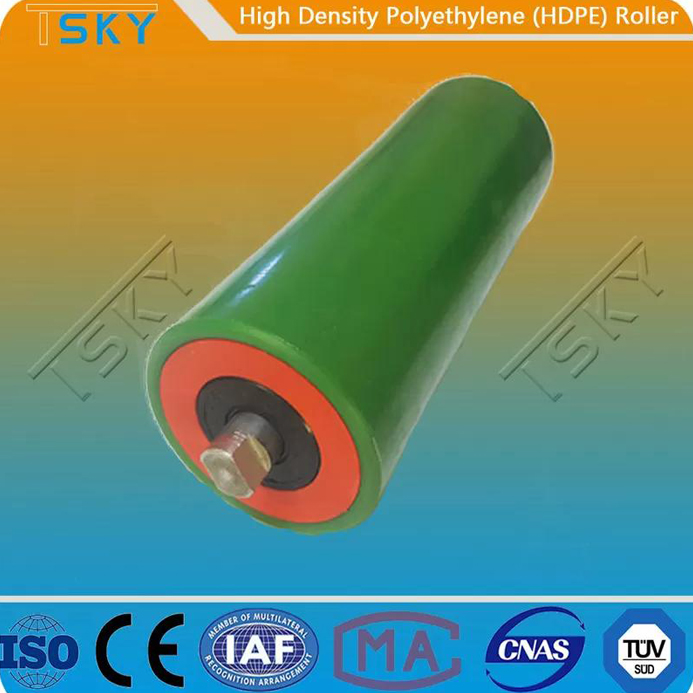

High Density Polyethylene (HDPE) Roller High Polymer Conveyor Belt Roller

High density polyethylene (HDPE) roller is a new generation of revolutionary product developed by our company. Its structure includes roller shell, bearing, shaft, bearing seat and sealing parts.

Through the close coordination of bearing housing and relevant seals, the bearing is strictly isolated from contact with the outside world to avoid contamination. Special labyrinth seal design can effectively protect the bearing for long-term and continuous operation, which can avoid the wear of conveyor belt and roller surface caused by the constant operation of the bearing of steel roller and ceramic roller & greatly improve the service life of the conveyor belt.

Through the test, the water can not go into the inside, which absolutely ensures the bearing in a good working environment and fully ensure the service life of the high density polyethylene (HDPE) conveyor belt roller.

The shell of the high density polyethylene (HDPE) roller is made of 300 molecular UHMPE pipe, which has the advantages of wear resistance, long life, no adsorption of iron powder, low friction coefficient with the belt, so that the service life of the conveyor belt can greatly extended.

The bearings of the high density polyethylene (HDPE) roller are fully sealed and maintenance-free lithium base grease lubricated, which have the advantages of flexible operation, long life and maintenance-free.

The bearing and sealing materials or the high density polyethylene (HDPE) roller are made of reinforced nylon injection.

The shaft is made of no. 45 cold drawn round steel.

Raw materials of the high density polyethylene (HDPE) roller make the roller wear resistance, impact resistance, self-lubrication, corrosion resistance, impact absorption, low temperature resistance, health non-toxic, not easy to adhere, not easy to absorb water and low density.

Compared with the traditional metal conveyor belt roller, the high density polyethylene (HDPE) roller has outstanding advantages in function.

1. The molecular structure of the high density polyethylene (HDPE) roller is winding linear arrangement, so its impact strength is very high. European and American countries have long used this material in bulletproof vest and armor protection.

In recent years, China is also developing and applying ultra-high materials to gradually replace the heavy metal materials.

Rollers made of high density polyethylene (HDPE) materials do not break as a result of prolonged rotation, fall or impact.

2. The surface of high density polyethylene (HDPE) material is smooth, non-magnetic, not easy to adsorb, small friction coefficient, and it has the characteristic of self-lubrication, which all can effectively reduce the friction between the surface of the roller and the surface of the conveyor belt, thus extending the service life of the conveyor belt.

3. The wear resistance of the high density polyethylene (HDPE) is the best of all kinds of engineering plastics. Experimental data shows that in relative conditions, its wear resistance is 5-7 times that of carbon steel or stainless steel.

Clearly, the high density polyethylene (HDPE) roller’s service life is more than three times longer than that of the steel roller.

4. The high density polyethylene (HDPE) roller has good corrosion resistance. At room temperature, any concentration of acid, alkali, salt, sulfur and other corrosive media are difficult to produce chemical reaction.

5. The water absorption rate of the high density polyethylene (HDPE) is extremely low (0.01%), that’s to say, its anti-adhesion performance is excellent. Even in the presence of water or oil, the dust can’t stick to the surface. Therefore, there is no need to worry that the high density polyethylene (HDPE) roller will scratch the conveyor belt because of adhesion materials. Besides, there’s no need to worry about the increase of rotation resistance due to scaling at the rotating part.

6. The specific gravity of the high density polyethylene (HDPE) is very light, only about 0.94, which is 1/8 or the carbon steel. Therefore, the high density polyethylene (HDPE) roller is easy to replace & reduces the working strength, which makes the electricity saving effect obvious. The high density polyethylene (HDPE) roller makes half as much noise as the steel roller, so it can operates noiselessly, which can eliminate noise pollution and clean the working environment.

7. The high density polyethylene (HDPE) roller has anti-static and flame retardant properties and can work under-269°to +80° environment for a long time. When it’s used in special environments such as coal mining, the safety can be ensured.

24-hour hotline:

24-hour hotline:

Add a micro signal:

Add a micro signal: